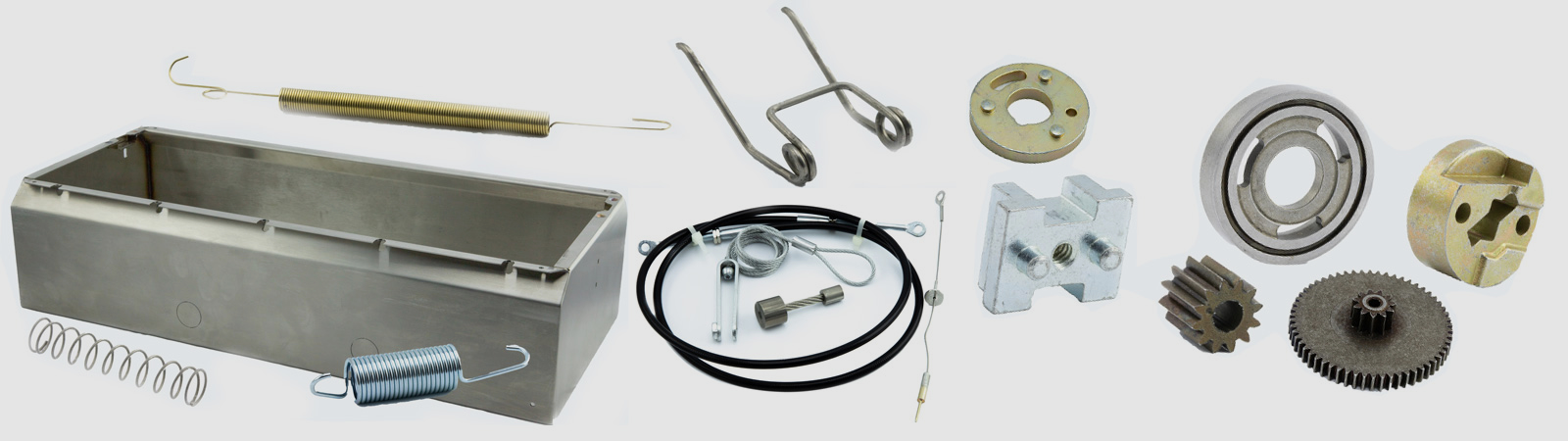

Metal Fabrications

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. Typically large fabrication shops employ a multitude of value added processes, including welding, cutting, forming and machining.

Manufacturing Capabilities

- Equipment

- TRUMPF TruFiber Laser 3030

- TRUMPF TruBend Press Brakes

- Amada Rotary Laser

- Amada CNC Press Break

- Cold Saw, Marvel Saw, Hyde Saw

- 2 gantry style Cutting Laser and one Laser Press

- Prototype and low volume production

- Thickness up to 1 1/4” CS and ½” SS

- Laser Press – ½” punching capacity, 20 ton maximum

- 2 CNC Brake Presses for rapid setup and process repeatability

- Boring Forming, Riveting, Tumbling

- Welding

- Miller PerformArc Robotic Welding Systems

- Resistance welding capabilities, both projection & spot welding

- TIG Welding

- Manual & Robotic MIG Welding

- In-house welding fixture design, build & maintenance

- Additional Services

- Parts Tumbler, Grinding, Assembling, Bending, Rolling, Polishing

Materials

- Cold Rolled Steel, Aluminum, Stainless Steel, DOM Tubing, Copper, Brass

Powder Metal

The powder metal (also called sintered metal) process consists of three basic steps; powder blending, die compaction and sintering. Dry powder is pressed into a mold that produces precise parts and then goes through a sintering process to create a stable part. This process is best suited for smaller complex parts that require tight tolerances.

Manufacturing Capabilities

We specialize in tight tolerance sintered metal component parts. Our diverse molding equipment allows for flexibility and repeatability throughout the plant. Our max tonnage is 500 tons. We focus on excellent surface finish and extremely tight tolerances (+/-.0025).

Materials

- High Strength Steel, Stainless Steel, Bronze, Brass, Soft Magnetics

Wire Rope & Lanyards

Wire rope is a type of rope which consists of several strands of metal wire laid (or ‘twisted’) into a helix. Initially wrought iron wires were used, but today steel is the main material used for wire ropes. Assemblies are quite common using wire rope and other components.

Manufacturing Capabilities

- Mechanical Wire and Cable Assembly

- Crimping, Swaging

- Laser Welding, Plasma Welding, Resistance Welding

- Nitinol Shape Setting

- Contract Cleaning Assembly

- Cross Sectioning

- Proof Loading, Tensile Testing

- Part Marking

- Bar Code Labeling

- Process Controlled Packaging

Materials

- Inconel, Nitinol, Stainless Steel, Tungsten, Polymers

Springs & Wire Forms

A spring is an elastic object used to store mechanical energy and is generally made out of spring steel. We specialize in compression, torsion and extension springs that primarily service the automotive, valve and engine markets. Our spring diameter capabilities range from 0.003 to 0.090 wire. Our wire form diameter capabilities range from 0.007 to 0.170 wire.

Manufacturing Capabilities

- 22 Coilers in various sizes

- Grinding

- Torsion Machines

- Extension Machines

- 24 Computerized Forming Systems

- Double Torsion Machines

Commercial

Commercial