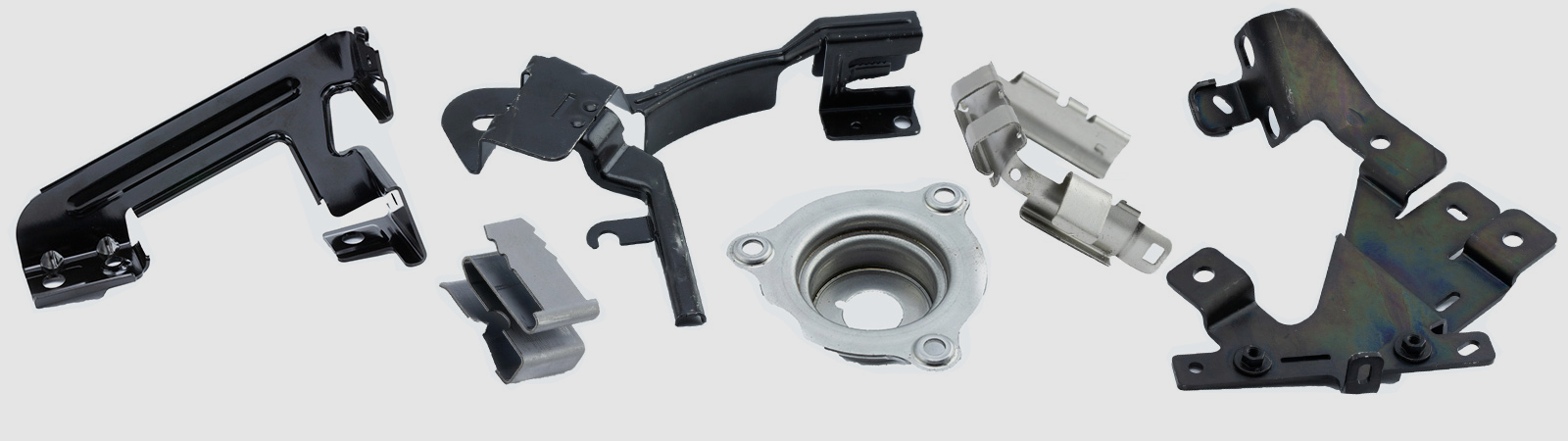

Stamping is a manufacturing process that utilizes coiled strip metal that passes through a series of progressive dies, punches and forms to produce a finished part. There are several different production metal stamping machines used in the industry. We specialize in progressive punch presses and multi-slide machines, each with advantages and drawbacks. Punch press machines utilize virtually unlimited tonnage applied to the work for greater forming. Speed of these machines is also a benefit in some cases. Punch presses utilize a progression of dies in one unitized master tool. These tools are costed based on the intricacies of the finished part. The part progresses through the die into stations on a carrier strip and is cut off in the last station of the die. Multi-slide machines utilize coil strip or ribbon metal which passes through a punch press section that blanks out specific features. The part is then separated from the carrier strip and is sent into the forming or slide section of the machine. Form tools are located at right angles to each other, operating off cams in a horizontal or vertical plane and a center forming post. Each of these elements can be tooled to perform specific bending, forming, assembly, or part removal function. Multi-slide tooling tends to be less costly and more versatile than punch press tooling. Part configuration and quantity will determine what type of metal stamping machine is best to produce a finished part.

Manufacturing Capabilities

- Punch Press – 60 to 600 ton mechanical presses

- Medium to Long runs

- Material Dimensions .010” to .280”, up to 24” wide

- Hi/Lo Carbon Steel, Brass, Copper, Stainless Steel, Special Coatings

- State of the Art Equipment

- Electronic Feeds

- In-Die Tapping

- In-Die Sensing

- Quick Die Change Clamping

- Slide Forming

- Optimal run speeds, lower tool cost, reduced scrap

- Ribbon parts from stock or custom tooling

- Feed length to 15”, width to 3.75”, thickness to .090”

- Process integration can reduce secondary forming steps

- Laser Forming

- TRUMPF TruFiber Laser 3030

- TRUMPF TruBend Press Brakes

- 2 gantry style Cutting Laser and one Laser Press

- Prototype and low volume production

- Thickness up to 1 1/4” CS and ½” SS

- Laser Press – ½” punching capacity, 20 ton maximum

- 2 CNC Brake Presses for rapid setup and process repeatability

- Numerous Manual Brake Presses

- Boring, Forming, Riveting, Tumbling

- Welding

- Miller PerformArc Robotic Welding Systems

- Resistance welding capabilities, both projection & spot welding

- Manual MIG & TIG Welding

- In-house welding fixture design, build & maintenance

- Robotic MIG weld cell

Materials

- Copper, Brass, Steel, Stainless Steel, Aluminum

Commercial

Commercial