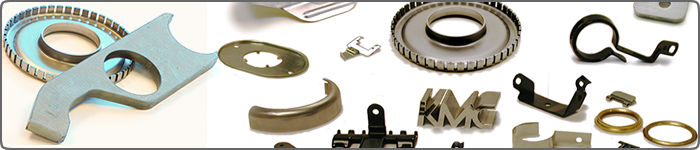

- We represent KMC Stampings, a leader in medium to high volume metal stampings, and collaborate with our customers to help them develop solutions that are high quality and cost effective, with engineering and manufacturing leadership, all done locally in our Wisconsin facilities.

- Our process begins with an idea, a need or an obstacle. Our customers challenge us to design and manufacture a customized solution that is faster to market, better quality and more cost effective than ever before.

- From concept through production, to ongoing service, we manage a part through its entire life cycle. We collaborate with our customers to develop solutions that give them a competitive advantage.

| PRODUCTION CAPABILITIES |

| Stamping – 18 progressive die stamping presses ranging from 60 to 600 tons, supporting programs requiring 10,000 to 7 million parts per year Laser Cutting – dedicated laser fabrication facility with 4 high speed laser and laser/punch combo machines and 7 press brakes, all used to support heavier gage materials and programs requiring less than 10,000 pieces per year In-House Tool Design & Manufacture – 110+ years of manufacturing service has led to expertise in the art of designing and manufacturing tools that are precise, repeatable and durable Welding & Assembly – specialized equipment including manual MIG/TIG/Robotic welding stations, programmable DC torque tools and custom fixtures to ensure we produce the highest quality assemblies Finishing & Coating – along with our high quality in-house vinyl coating process, KMC partners with an extensive group of ISO/TS and IATF certified partners to support our customer’s requirements for electroplating, painting, Ecoating, cleaning and more Quality Inspection – we apply the latest in quality and inspection technology to facilitate our APQP and production processes, insuring that your parts will be made to print every time |

Commercial

Commercial