We offer a one-stop solution for value-added aluminum extrusions, focused inventory plans resulting in greater cost controls, quality improvement ideas due to extensive product and process knowledge, and lead time reduction utilizing our lean manufacturing principles.

Aluminum’s natural metallic and reflective appearance can add an aesthetically pleasing look to your assembly. Combine this with the seamless nature of extrusions, the complexity of the design, the corrosion-resistant nature of aluminum, and its ability to accept a wide range of finishes – aluminum extrusions offer advantages unmatched by other materials and processes.

Anodizing occurs within the aluminum, becoming an integral part of the surface. An anodized surface is durable, it does not peel, and it is resistant to corrosion. Anodizing prevents further oxidation from occurring and therefore extends the life of the product.

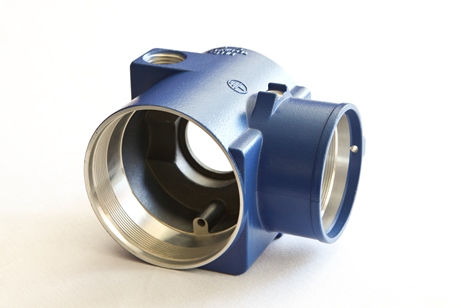

If you are looking for a machined casting, then look no further. Our team will manage your project from sourcing the raw casting to machining your part to print. Our casting supply base is large and proven. Our equipment diversity guarantees that your product is produced with the most cost effective manufacturing process. Whether you are looking for a CNC, Swiss, or screw machine part, our portfolio of manufacturers has you covered. Please contact us for a quote or for more information.

If you are looking for a machined casting, then look no further. Our team will manage your project from sourcing the raw casting to machining your part to print. Our casting supply base is large and proven. Our equipment diversity guarantees that your product is produced with the most cost effective manufacturing process. Whether you are looking for a CNC, Swiss, or screw machine part, our portfolio of manufacturers has you covered. Please contact us for a quote or for more information.

Offering a one-stop solution for value-added aluminum extrusions. Focused inventory plans resulting in greater cost controls. Quality improvement ideas due to extensive product and process knowledge. Lead time reduction utilizing our lean manufacturing principles.

Offering a one-stop solution for value-added aluminum extrusions. Focused inventory plans resulting in greater cost controls. Quality improvement ideas due to extensive product and process knowledge. Lead time reduction utilizing our lean manufacturing principles.

Commercial

Commercial